The production of solar energy from renewable sources (Sun) continues to grow worldwide. The (IEA) International Energy Agency estimates that 4500GW (Giga-watts) of new green-power will be installed worldwide by the end of 2024, 2/3rd of which will be photo-voltaic (PV) systems. But how can we build a photo-voltaic system? How do we install solar panels? And how do such solar systems work?

Photovoltaic park: is built and how it works:

What is involved in the construction of a solar energy farm, breaking ground at the construction site and the system starts producing energy? And how do photo-voltaic systems actually work once it is installed? How is solar green energy produced? Let’s go further into both processes step by step.

Photo-voltaic: Main Elements:

Each solar park has different specification, i.e. capacity, production, size, layout, topography and installed capacity, but the main required elements are always the same. The detail is as under:

- Photo-voltaic panels: Devices consist of a photo-voltaic module or set of modules mounted on a supporting structure.

- Photo-voltaic modules: Devices made up of a mosaic of inter-connected photo-voltaic cells. These cells are the most basic element of a photo-voltaic system. They directly convert solar energy into electrical current creating a phenomenon called the photo-voltaic effect.

- Tracker: A supportive structure on which photo-voltaic modules are installed which enables automatic adjustment of module orientation. Basically, the tracker allows the solar panels to face the sun as it moves across the sky in order to maximize the production of electricity.

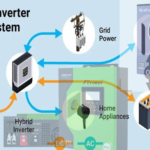

- Inverter: A device that converts the direct current (DC) produced by modules into alternating current (AC) and also to store the solar energy in lithium batteries or acid batteries.

- Transformer: A high electric device which is capable of raising or lowering the voltage before feeding it into the grid.

- Access roads and drainage works: It is useful for inspection and monitoring. It may protect the system in case of rain, flooding or any other critical situation.

- Conduit: Protective tubing which is usually placed underground. It holds the electrical wires that connect the PV system to the primary substation of the power grid operator.

How to Build a Solar System Park: Step by Step

Before the opening of the construction site, the authorization process must be completed according to formal public administration agreements. The agencies involved may authorize the construction of the solar park and may issue some requirements for the project. The Archaeological Superintendent’s office requires an archaeological assessment to be conducted. They may require the presence of an archaeologist at the construction site.

This phase is followed by preliminary activities prior to the opening of the construction site. These activities include conducting tests necessary for planning and design (such as seismic, geological and geotechnical tests to verify soil characteristics). The area may be checked for the building of the park and its suitability for sunlight. The soil may also be checked for the installation of foundation for solar panel stand.

After these required survey, construction begins with setting up the construction site. It involves creating access roads, installing temporary offices, temporary kitchen, living rooms and toilets etc. It is followed by the construction of civil works, like drainage work, such as culverts and lamination tanks, which are essential in order to protect the system from simple rain or flood events. At this stage, “earth-moving” also takes place, in which the ground is reshaped in accordance with construction plans.

At this point the mechanical installations start which can be divided into three phases:

- In this phase, the tracker poles are placed properly, which is generally done by means of a pile driving machine that beats the mining poles into the ground to a depth determined in the executive design phase.

- In the second phase, complete the installation of the trackers onto the poles is finalized, which is done manually, with the support of fork-lifts for lifting. The types of trackers may differ based on the number of modules they need to move.

- In the third phase of mechanical installation, the installation of the photovoltaic panels takes place. This action is also done manually, and a team of four people can install 250 panels per day. For making sure a good energy yield, it is essential to identify the optimal spacing between the trackers. The optimal space may enable the PV modules to follow the movement of the sun throughout the day. It may also keep the orientation of the tracker as perpendicular as possible to the sun’s rays in order to avoid generating shadows.

All these activities are facilitated by the pre-assembly of many components. These activities may be carried out in a special area by dedicated teams so that only the final assembly remains to be completed in the field.

Then, after the installation of tracker, it is time for electrical installation, where wiring, terminals, and electrical connections are arranged. In particular, modules are wired in a series pattern to form strings. A high level of precision is needed because string cables can feed into string boxes to optimize the amount of cable installed and increase the reliability of the system.

The final and decisive phase is commissioning, which is divided into Cold and Hot commissioning. In the start, all electrical tests are performed before connection to the power grid. Then, the system is energized in reverse: starting from the power grid to the modules. This whole process may be performed under the supervision of the Commissioning Manager. At this point, the system is ready to begin generating power.

Q. How is a ground-mounted photo-voltaic system working?

Photo-voltaic system starts with the modules. It converts the solar energy that is received from the sun into electrical energy, called photo-voltaic effect. Photo-voltaic module is composed of a semi-conductor material called silicon. Silicon is one of the most wide-spread minerals on Earth and is easily available.

Semiconductors are referring to materials that become conductors of energy when their component atoms receive a sufficient amount of energy for electrons to move. It causes the electrons-flow and the production of electric current. In the photo-voltaic modules case, solar energy comes from the sun in the form of photons. When sufficient solar energy comes, the electrons in silicon break its bond and move freely. The photo-voltaic effect occurs. Semi-conductors (Silicon) have few free electrons and therefore have a low conductivity. To increase the conductivity, doping techniques silicon crystal is used. The impurities, like phosphorus or boron atoms that have a different electron number than that of silicon, are placed inside the silicon crystal. These results in electrons to break the bond of electrons and thus are free to move and conduct energy.

Solar cells are made up of alternating different layers of doped silicon crystals. It usually uses a p-n junction that connects boron-doped (p, i.e., positive) silicon to phosphorus-doped (n, i.e., negative) silicon. Thus it creates an electric field which provides a preferred direction for the moving electrons. In this way, when a photon from the sunlight hits one of these junction areas with sufficient energy, it breaks the p-n bond. Hence it releases electrons that will move along a certain path and creates a flow of electricity that can be collected. In this way, each of the formed cells can produce a weak voltage, around 0.50 to 0.60V.

Many of the solar cells are connected together to form a photovoltaic module. Multiple connected modules in series make up photo-voltaic strings. Multiple strings that are connected together, in parallel, form the solar generator or photo-voltaic array.

The main function of inverter is to transform the direct current produced by the modules into alternating current. There are several types of inverters. The most common types are central inverters and string inverters. Strings inverters can be connected together via string boxes and converge in the central inverter or connect directly to the string inverter. The distinguished factor between the two types of inverters is power. A central inverter is very large and collects power from 1 to 4 MW, while, string inverters can handle the power of 150/300 kW. They can be placed in the field close to the strings, thereby reduces cable lengths and dispersion.

The inverter works on low voltage (up to 1000V AC) and additional voltage conversion is required. But when high power comes into the field, it is necessary to switch to medium voltage (10 to 40 kV) using a transformer.

In smaller plants up to 10 MW, energy runs directly from the transformer to the delivery sub-station. It is fed into the distribution grid. In large plants, it’s necessary to go through an electrical sub-station that collects the medium-voltage lines and conveys them to a large transformer. It takes the power from medium to high voltage, i.e., up to 120/220 kV, before it is fed into the grid.

In the current time, the efficiency of a photo-voltaic system is about 24%. It means that the technology allows a quarter of the solar energy received by the modules to be transformed into electricity.